The role of inventory management in multi-channel fulfillment

You cannot cater to a market spread across multiple channels without meticulous inventory management.

Why? Because without it, you’re navigating blind. Imagine trying to meet customer demands, keep your shelves stocked, and avoid costly overselling or underselling — all without a clear, real-time view of your inventory. It’s a recipe for chaos.

Meticulous inventory management is your roadmap — ensuring you know exactly what’s available, where it is and when to restock. It ensures every channel runs smoothly.

In this article, we discuss multi-channel fulfillment and inventory management and give you five pro tips for navigating effective inventory management.

What is multi-channel fulfillment?

Multi-channel fulfillment is the process of managing inventory and orders across multiple sales channels to ensure timely delivery to customers. When your products flow smoothly from your warehouse to customers, no matter where they choose to shop — be it your online store, Amazon or through your latest social media campaign, you make shopping easier for customers.

But multi-channel fulfillment demands a higher level of coordination in handling inventory, logistics and customer service across diverse platforms.

The different sales channels include:

- Online stores: Your own website or ecommerce platform where you control the entire customer experience.

- Marketplaces: Third-party platforms like Amazon, eBay and Etsy that offer vast reach but come with their own set of rules and fees.

- Social media platforms: Direct selling through social media sites like Facebook, Instagram and TikTok, where shoppers can purchase products without leaving the app.

Mastering multi-channel fulfillment is not just about expanding your sales avenues. It’s also about ensuring that no matter where your customers find you, their buying experience is smooth, reliable and delightful.

What are the benefits of multi-channel fulfillment?

Multi-channel fulfillment gives you an opportunity to expand your reach, enhance customer satisfaction and optimize inventory management. By selling across multiple platforms, you tap into diverse customer bases, and reach the same customer on multiple platforms.

Here are four key benefits:

- Diversifying sales channels helps you reach new customer segments and boost overall sales.

- Relying on multiple platforms reduces the risk associated with market fluctuations or platform-specific issues.

- Being present on various channels increases your brand’s exposure and recognition.

- Gathering data from multiple channels provides a comprehensive view of customer behavior and preferences.

The biggest benefit of multi-channel fulfillment is increased customer convenience. Being able to shop for and receive products through multiple channels like online, in-store and phone, gives customers flexibility and choice in how they want to engage with a brand. For example, a customer may browse products on a website, and then go to a physical store to see, touch and try on items before purchasing and having them shipped directly.

Peter Wuensch, V.P. Industrial at Knape Associates

What are the challenges of multi-channel fulfillment?

Multi-channel fulfillment comes with a high degree of complexity. You need sophisticated systems and processes to track inventory, pricing, customer data and shipping details across multiple channels.

You also need to configure carriers and distribution networks to ensure fast, low-cost delivery of individual items to customers. This can be an operational nightmare for unorganized teams and a heavy lift for even the most meticulous managers.

One of the trickiest omni-channel problems I’ve faced was maintaining consistent customer data across multiple touchpoints. With customers interacting through the web, mobile app, call center and in-store, it was a challenge to keep their information and history synced up in real-time.

Mike Szczesny, Owner & Vice President of EDCO Awards and Specialties

What are the benefits of effective inventory management in multi-channel fulfillment

Effective inventory management in multi-channel fulfillment is not just about keeping track of products — it’s about embedding a layer of logic into operations. Here’s how:

Improved stock accuracy and reduced stockouts

Accurate inventory management means knowing exactly what you have and where it is. This precision prevents stockouts and overselling, so none of your customers are on the receiving end of “out of stock” messages after placing orders.

Enhanced customer satisfaction and loyalty

When customers consistently find what they’re looking for, they’re happy. Happy customers come back. They tell their friends. Effective inventory management builds a loyalty loop without you having to deploy elaborate rewards programs.

Better demand forecasting

Good inventory management isn’t just reactive — it’s proactive. By analyzing trends and data, you can forecast demand more accurately. This foresight means you’re always prepared, stocking the right products at the right times and avoiding excess or obsolete inventory.

Increased operational efficiency

When tasked with repetitive processes, human beings are prone to making mistakes. They’re best left to strategic tasks and planning. Inventory management minimizes the scope for careless errors. Automating tasks, creating a system of notifications and balancing inventory boosts operational efficiency.

Plus, by avoiding overstock and stockouts, you cut unnecessary costs, making your fulfillment process lean and mean.

What are the challenges of multi-channel inventory management?

Multi-channel fulfillment can be an operational and managerial balancing act. On the one hand, it’s nice to see customers piling in from every door; on the other, you must cater to them all at once.

Here are some common issues businesses face:

- Overselling and underselling: Traditional inventory management can leave you without the proper means to cater to your customers. You might be selling out your most popular products while your other products are gathering dust in a corner because of poor manual management.

- Managing multiple locations, warehouses, and fulfillment centers: It’s not just about knowing where everything is; it’s about ensuring it’s in the right place at the right time.

- Integration complexities: Connecting and synchronizing inventory data across various sales channels, ERP systems and third-party logistics providers can be a labyrinthine task, often leading to data discrepancies.

4 strategies for effective inventory management in multi-channel fulfillment

Effective inventory management requires you to take stock of every layer of interlinking. This means evaluating:

- How stock levels connect to demand

- Where overselling or overstocking happens most frequently

- How inventory ties to each other

Let’s look at four strategies for managing inventory effectively:

(Heads up: Most of these are easier — or only possible — via an inventory management system.)

1. Maintain buffer stock to prevent stockouts

Buffer stock is like having a reserve fuel tank — you don’t want it to run out in the middle of nowhere. It’s about anticipating demand fluctuations to stay prepared for spikes (and making sure you don’t miss out on the extra revenue).

Inventory management software like Linnworks allows you to create notifications when stocks fall below a predefined threshold. It also automates the creation of POs so you don’t waste time manually ordering buffer stock.

Effective inventory management begins with maintaining a buffer of essential items. This safety net ensures you can meet demand even during unexpected spikes or delays. By analyzing historical data and trends, you can strategically set buffer levels that balance the risk of stockouts with the cost of holding extra inventory.

Peter Hoopis, President and Owner of Hoopis Pickleball

2. Implement automation for real-time updates

Real-time updates help prevent embarrassing out-of-stock situations. They also help you understand patterns in different product categories and trends across channels.

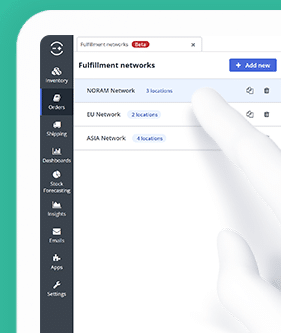

Inventory management software like Linnworks can help you sync automations across multiple warehouses so your team doesn’t have to coordinate via Slack, emails, or phone calls. This frees up their time and provides an instant overview of your inventory levels.

My top tip for implementing real-time automated inventory updates is this: start small and scale up gradually. Don’t try to automate your entire inventory all at once. Begin with your highest-volume or most valuable products first. This allows you to work through any integration issues and optimize processes before rolling it out across your full inventory.

Mike Szczesny, Owner & Vice President of EDCO Awards and Specialties

3. Sync inventory levels across channels

This way, you won’t have to allocate inventory based on the channel’s historical data. You can just plug in your overall inventory, and your inventory management system will update you on low stock levels.

Syncing your stock levels also gives you the option to view trends across different sales channels. For example, you may notice that your social media stores sell five dresses a day, but your website sells 20. But during bank holidays, the numbers even out.

“The trickiest problem I’ve encountered was integrating our brick-and-mortar store inventory with our ecommerce platform. Customers expected us to have real-time visibility into product availability across channels, but our legacy systems made this extremely difficult.

The solution was a full technology overhaul. We implemented new POS and inventory management systems that integrated with our ecommerce platform. This gave us a single view of inventory and order history across all channels. We also added options for customers like “buy online, pick up in-store” and store-to-door shipping.

The project took 18 months and was a significant investment, but it was worth it. We saw a 15% increase in online conversion rates and a 10% lift in in-store sales from customers who first browsed online. Delivering true omni-channel retail is complex, but getting it right pays dividends in the customer experience.

Shawn Stack, Founder and CEO of Hallmark Timmins

4. Optimize warehouse and storage management

Storage management isn’t just about stocking relevant items together, it’s also about creating a base layer of logic for future reference. Here are a few tips:

- Segment your SKUs based on sales velocity and storage requirements. High-velocity items should be easily accessible for quick fulfillment, while slower movers can take a backseat in sub-optimal locations.

- Design your warehouse layout like a well-planned city grid. Ensure fast-moving items are closer to packing stations and shipping docks, minimizing pick-and-pack times and optimizing workflow efficiency.

- Keep your inventory in check with regular audits and cycle counts. It’s like giving your inventory a health check-up, catching discrepancies early and maintaining accuracy across all channels.

Inventory management as a first step

From preventing stockouts to boosting customer satisfaction, meticulous inventory management lays the groundwork for scalable multi-channel fulfillment. It’s one thing to offer buying options on multiple sales channels, it’s another to make sure they all work efficiently.

Get it right, and you’re not just managing inventory—you’re setting the stage for ecommerce excellence that boosts sales and loyalty.