How to manage ecommerce inventory

Today’s shoppers expect the buying journey to be easy from their first search products through placing the order and onto quick, on-time delivery. This puts pressure on sellers to carefully manage ecommerce inventory even as they juggle customer requests, shipping deadlines, changes in the market and other day-to-day responsibilities.

Making sure your products are easy to find and ready to order is the first component of a great customer experience. Nine in 10 shoppers use convenience as a filter for online purchasing decisions, so it’s important to control and eliminate potential deterrents early. Complex supply chains also pose challenges. Effective inventory management involves acquiring, storing and selling products across multiple channels. It also requires your business to perform a balancing act, weighing consumer needs against the capabilities and requirements of manufacturers and suppliers.

We’ll share how you can manage ecommerce inventory while also managing your orders, storage, shipping, customer service and other business-critical tasks. You’ll also learn why a modern inventory management strategy is important and discover techniques to improve inventory control and your view of stock levels.

Why Is Inventory Management Important?

Inventory management covers everything from initially acquiring products to storing and eventually selling them. This process requires a complete understanding of your stock levels, including where products are and where they’re going. But inventory management is more than just maintaining product flow. It helps you prevent stockouts, enables you to track and sell items across multiple locations and ensures that your records and inventory data are accurate.

Most importantly, proper inventory management ensures that your products are available when your customers need them. Forecasting isn’t an exact science, but inventory management processes collect and analyze data to help predict the amount of stock you need to meet anticipated demand. Furthermore, accurate forecasts can save on costs associated with unsold inventory or stockouts.

Inventory Management Techniques

ABC Analysis

ABC analysis is a technique that assigns three categories (A, B and C) for products based on the value they provide a business. Items are ranked based on demand, cost and risk, then assigned “Class A” for the most important products, “Class B” for the next most important and “Class C” for the least important. As most of your revenue will come from Class A products, you also use this analysis to find opportunities to negotiate with suppliers for better pricing or other incentives.

Bulk Shipments

This technique involves buying, storing and shipping inventory in bulk. While this approach requires a larger initial investment, the savings provided by purchasing large volumes can outweigh the upfront costs. Bulk shipping is one of ecommerce’s predominant techniques and can be especially beneficial for products with a long shelf life. If you have the warehouse space and capital to invest, bulk shipments can be very profitable.

Consignment

With consignment inventory management, your business takes possession of inventory from a supplier before paying for it. However, the supplier retains ownership of their product until your company sells it. This technique can allow for more readily available inventory but requires coordination to ensure that inventory and sales needs are aligned. Consignment has potential for ecommerce sellers, but this technique requires regular evaluation of products and inventory. If you choose to pursue this option, make that the focus of your ecommerce store. Make sure buyers can easily find not only your consigned products but also your related policies.

Cross-Docking and Dropshipping

Cross-docking relies on having your inventory stored in warehouses for as little time as possible, if at all. Instead of being stored in warehouses, items are moved directly from the supplier to the delivery truck for next-level manufacturers, retailer stores or consumers. With dropshipping, products are shipped directly from the manufacturer to the consumer after the distributor sends the order. This can be an easy and inexpensive way to get started in ecommerce, but it’s highly competitive and not typically as profitable as other methods.

Cycle Counting

Cycle counting involves matching physical inventory counts with inventory records and databases on a recurring basis. This technique provides a system for checks and balances to ensure that products available on shelves match inventory records. Any inventory management technique should include a regular audit to minimize disruptions and control cost, though many businesses conduct cycle-counting stages to focus on a manageable subsection of inventory.

Demand Forecasting

Demand forecasting is the process of predicting consumer demand for a product over a period of time. This helps you avoid overselling and optimizes inventory to match demand. Using an inventory management system can help you monitor inventory and history across all locations in real time, leading to more efficient, accurate and effective forecasting.

Economic Order Quantity and Minimum Order Quantity

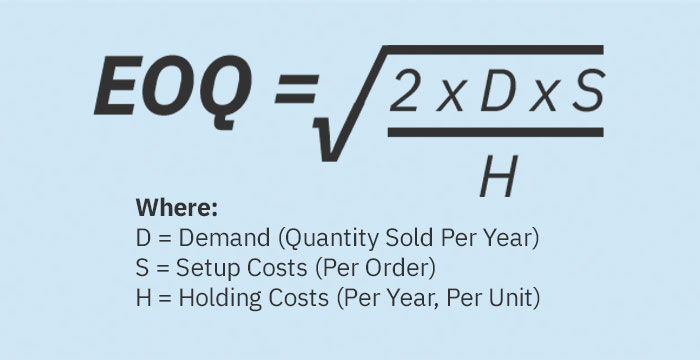

The minimum order quantity (MOQ) technique can be used when purchasing large quantities of inventory from a wholesaler in order to reduce the cost. Economic order quantity (EOQ) is a formula that shows how much inventory your company should order to minimize associated inventory costs such as logistics and storage. EOQ is calculated using the following formula:

FIFO and LIFO

The first in, first out (FIFO) process involves moving the oldest stock first, which keeps inventory moving. Last in, first out (LIFO) takes rising prices into account, meaning the last inventory to arrive is also the most expensive and should be sold first. Both models have their merits, so you’ll need to review how your ecommerce business costs will change throughout the year. If you expect inventory costs to rise, for example, LIFO could reduce your company’s taxable income.

Just-in-Time Inventory

Just-in-time inventory requires working closely with suppliers so that raw materials arrive just in time to begin production. This allows companies to hold the minimum amount of inventory needed to meet demand.

Other inventory management techniques include:

- Lean inventory management

- Materials requirements planning

- Reorder point formula

- Perpetual inventory management

- Safety stock

- Six Sigma or lean Six Sigma

Benefits of an Inventory Management System

Automation

Manual processes can be tedious but are a common starting point for smaller businesses. As your company scales, however, you’ll need to streamline operations to keep pace with demand or risk losing potential sales. Automation can turn time-consuming manual processes into self-managed systems, which saves countless hours and avoids many of the risks of human error. Automation’s benefits are especially important for ecommerce businesses that expand to additional sales channels such as new marketplaces or social media.

Improved planning and forecasting

Inventory management systems can provide reporting and valuable insights to help with planning and forecasting. When these systems integrate with sales channels and shipping and third-party logistics (3PL) providers, your business can gather accurate, real-time data for more precise predictions. Inventory management systems can also streamline storage processes and reduce associated costs, as inventory is cycled efficiently and less unsold inventory on shelves.

Reduced Costs

Inventory management systems can reduce costs in numerous ways, such as giving your team a more accurate view of inventory, which makes the pick, pack and ship process more efficient. These systems can also help you avoid overstocking, which reduces the costs associated with warehousing or selling the product at a reduced price. With less room for human error, the cost of resolving issues related to manual workflows can also be reduced.

Expanding Operations

Centralizing your inventory in an inventory management system can also make it easier to add new sales channels for your business. Inventory management systems that integrate with marketplaces such as Walmart or Amazon can simplify setup processes and help your business connect with shoppers more quickly.

Once you’re up and running on new sales channels, inventory levels can be synchronized and viewed in real time from a single location, which gives additional control and provides a holistic perspective for forecasting. Inventory management systems can also help you more effectively establish a supply chain diversification strategy to identify additional suppliers and reduce risk.

Improving Your Inventory Management

Ecommerce continues to grow in use and importance for sellers, and so has the complexity of selling online. Shoppers can be found across a variety of channels, locations and devices. To stay competitive, you need to adapt to customers’ needs while closely monitoring your inventory so it’s ready whenever and wherever customers want it.

With inventory management software like Linnworks, you can avoid over- or underselling by tracking inventory in real time across all of your sales channels from one, easy-to-manage central platform. This allows you to sync inventory across warehouse locations and sales channels for a complete view of your business.

Inventory management systems can also provide live consumption data, which tells you where your stock needs to be to meet demand, and historical sales data, which improves the accuracy of demand forecasting. Learn more about how automation can help with inventory forecasting.