Covid-19: Supply Chain Risk Management Takes Center Stage

Uncharted Territory

Almost every business has seen a disruption to their supply chain. The current health crisis is being described as many things. To the supply chain world, it’s a major wake-up call. To the eCommerce world, it’s a major challenge to see if it can keep up with increased demand. Luckily, most agree that the supply chain world will adjust and become increasingly conducive to eCommerce and omnichannel models.

But in order for that to happen, adjustments will have to be made.

Right now in the US, more than 70% of businesses say they have enough stock to last through Q3. But what happens next? Supply chains will have to provide the answer.

Mitigating risk within supply chains is now top of mind for most, if not all industries. Given the weight of the current situation, it will be vital. In order to survive, many types of businesses will make efforts in that direction.

The Biggest Changes to eCommerce

Virtually all agree that there will be lasting effects on supply chains and consumer behaviors alike. For more traditional businesses, the resilience to shift the majority of operations to eCommerce is a major storyline.

With lead times up 200%, 95% of businesses have seen disruptions to their supply chains, it’s easy to see why a more rapid adoption of eCommerce is necessary.

A gradual embrace of eCommerce has been emerging on it’s own for some time. But with the sudden massive shift to online buying, fueled by fears of physical shopping, has led to a 25% increase in ecommerce shopping since the beginning of March.

It is important to note here that not all eCommerce is created equal in this situation. While certain household items, non-perishable foods and medical equipment are seeing soaring sales, other segments are not selling as much. Among SkuVault clients, we have seen major increases in orders for items such as hardware and apparel, and decreases for products like business supplies.

Some of that is due to the Amazon pivot that restricts non-essential items from shipping. Not surprisingly, UPS is feeling the pinch as well, and is adjusting their pricing structure.

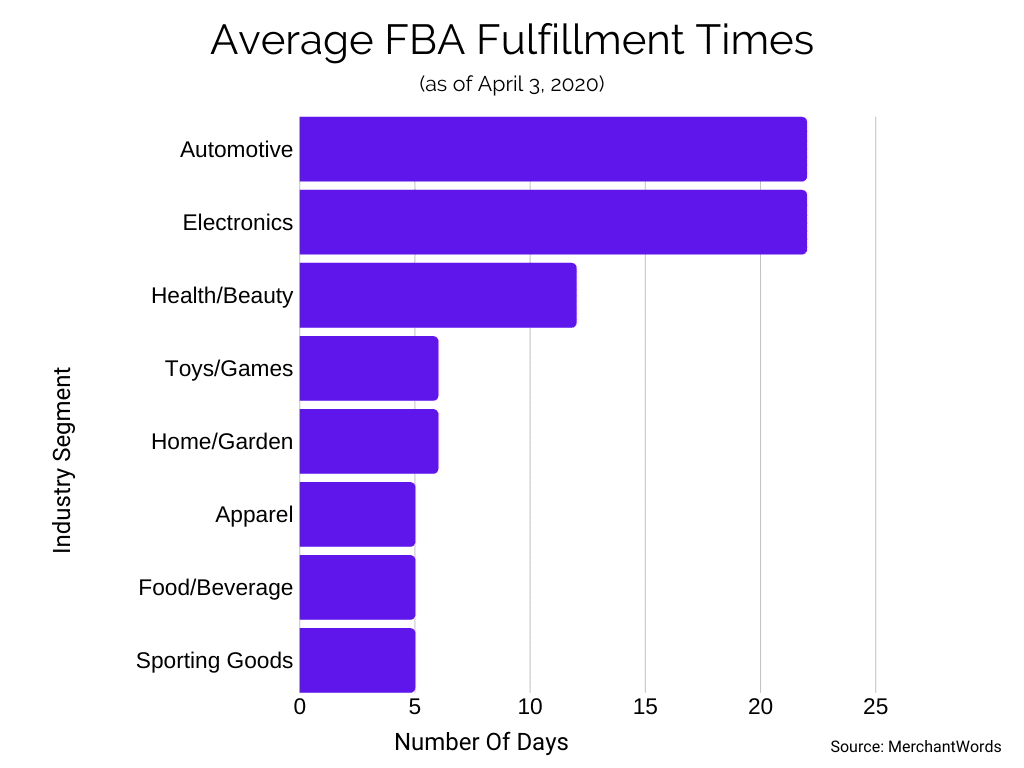

Let’s take a closer look at the changes to Amazon’s FBA fulfillment times to certain industries:

The big story is consumer psychology and behavior. And aside from the run on toilet paper, much of it could be predicted.

Stuck at home, many are going online to purchase books, puzzles and games. Many people are spending money on home improvement projects or purchasing home goods to make life indoors and in the backyard more enjoyable.

An Interconnected Supply Chain Means Everyone Feels The Pinch (Or Punch)

Another likely lasting effect is the shift to a more diversified supply chain. No matter your perspective, whether supplier, wholesaler, vendor or 3PL, all will remember the vulnerabilities that this crisis has exposed and all future planning will be done with the idea of limiting its impact in mind.

Not to mention, there is still much uncertainty in terms of what the future will look like. What we do know, is that eCommerce will play a major role.

Vendors, hit hard on multiple fronts like supply disruptions, staffing issues and low sales, will need to be able to find relief for these issues on multiple fronts.

Wholesalers and suppliers will also feel the pinch of supply and staffing challenges. They will also bear the brunt of increase of shipping costs as well as dramatic shifts in demand for certain products.

3PLs are seeing an increase in demand, simply due to the issues caused by Amazon and other staffing and fulfillment disruptions caused by the lockdowns.

Every link in the supply chain is interconnected, so what impacts one link is sure to impact the rest. And there is no doubt that all are going to feel the effects of the economic crisis that will result from extended periods of lockdowns, which has not yet fully come to fruition.

What this all means is that each group will start to feel the need for ways to quickly adapt and form new partnerships where needed, and on their own terms.

Quickly Adapting To Change

It has been both fascinating and humbling to hear stories about distilleries shifting to producing hand sanitizer instead of spirits, milliners pivoting to making masks, and manufacturers quickly ramping up ventilator production.

But there are a lot of businesses out there who just don’t have the scale or the margins to make such large-scale operational changes so quickly.

This is seen also with logistical struggles that many businesses and supply networks face in order to keep pace. The other complication is the massive disruption to sourcing, staffing and sales. Other issues being faced are increased demand for shipping, as well as capacity and on-demand training.

On the positive side, it has created opportunity. Not in the typical business sense, but in the way of problem solving that can truly benefit people worldwide.

The key to making this positive future a reality will be to not only have an agile and responsive business network (more on that later), but to have full visibility into your own operations with the ability to be nimble enough to quickly adapt when needed. Resiliency will be a new core value for many businesses.

Forecasting vs. Planning

Forecasting could not have helped anyone keep toilet paper in stock. No actionable data or report could have led anyone to believe they needed to make sure they had enough toilet paper in stock to cover the panic buying that ensued as the lockdowns began.

It has led many supply chain managers to question whether forecasting is even worth it, at least right now.

The main recommendation seems to be to replace forecasting with planning. Planning may seem like a loose term that could be synonymous with forecasting. Or, at least forecasting is thought of as a key component of overall planning.

But many supply chain professionals were able to see the writing on the wall as the situation rapidly escalated in China and beyond.

Inventory visibility, and by extension the supply chain and logistics infrastructure around commerce (especially online) will need to be a foremost priority, especially now that planning for worst case scenarios will become more top of mind.

A More Diversified Supply Chain

Many businesses were already in the process of supply chain diversification prior to the current health crisis. Due to the ongoing trade war with China, many were already realizing that putting so much reliance in one place was no longer practical. Especially as that place becomes increasingly volatile.

And that emerging trend may have helped soften the blow of current supply chain disruptions. We can be thankful for that.

The initial impact of the new virus in China led many US firms to make quick changes, even before it reached the US. Dual sourcing is already becoming a good way to prevent potential supply chain disruptions. Now, and in the future, it will become a necessity.

The need for diversified sourcing will be vital to mitigate disruptions, regardless of what those disruptions are.

In the US, we are already seeing more domestic sourcing for food items, and will likely see the same in other sectors as well.

A Closer Look At Industries Affected

Search trends on Amazon reveal that social distancing is having a major effect on consumer behavior. This should surprise no one. But what is surprising is the ways businesses are adapting to help people get the items they need.

It means that Amazon has made major changes to their fulfillment model, which has caused sudden changes to order fulfillment.

While most retail segments are seeing disruptions, some are seeing skyrocketing sales. It’s no surprise that personal care products, healthcare and non-perishable foods are selling in high volumes, even though their supply chains are stretched thin in some cases.

Resilience Planning Will Become Increasingly Important

Who would have ever thought that Amazon would ever lag in terms of fulfilment?

As of February 2020, most people would laugh at a notion like that. Yet, here we are! As we said earlier, resiliency will become a core value and with that comes the planning for how best to achieve it, and make it sustainable.

To make it in the post-corona world, you have to start acting now, which is certainly not easy given disruptions to the current business models, end consumers, suppliers, and wholesalers, everyone is seeing the effects of reduced and forced-to-be-remote staffing,

Since many economic indicators are unpredictable at the moment, planning for multiple scenarios is key.

How To Build an Agile Supply Chain And Logistics Environment

Data will be key (as always)

What is planning without measurement?

Even with traditional forecasting models being sidelined temporarily, its important to know what types of metrics to evaluate when planning.

The ability to make quick and necessary adaptations will be crucial to the survival of many businesses out there. And that is achieved through access to data.

But it won’t be sales forecasts, as we’ve mentioned. Rather, it will be metrics around your own internal operations, what you can handle, and plans for different types of scenarios.

You’ll need to know exact data points about overall inventory levels, reorder points, safety stock. Also, down to the nitty gritty details of tracing back any error to its origin for a quick correction.

In many ways, your warehouse needs to be designed for your inventory, and not your inventory designed for your warehouse.

And you will also need access to information from outside of your organization; for new opportunities. Access to data as well as new fulfillment networks is a trend we think we will start seeing a lot more of.

Focus On The Customer Experience

Now is an important time to focus on your customer experience on your website, and on your sales platforms. This will be your only interaction point with them for the time being, so it has to count.

Customer experience will also remain important in your marketplaces. While things may be going haywire with Amazon and eBay fulfillment at the moment, the dust will settle. That’s why it will be more important than ever to take a close look at your presence on these channels.

And with Amazon and eBay specifically, it will be vital to focus on your keywords. Good old fashioned keyword optimization for your listings is a good way to remain efficient and competitive. It will also provide you with valuable data that can be used for planning.

Creating your own fulfillment network is one way a lot of sellers are adapting to the current struggles Amazon is having.

To do that, you need 4 main components:

Channel Management

Take a hard look at your channel management infrastructure to make sure your sales activity remains lean across your network. And if you have brick and mortar stores, please make sure that your BOPIS model is well equipped.

Inventory Management

Accurately managing inventory will be one of the best ways to ensure that your in-house fulfillment engine is strong enough to weather any storm. That is how businesses will be successful in the post-corona world.

With storage demand up at 35% of ports you will see an increased need for lean warehousing and inventory management practices.

Shipping And Fulfillment

Order fulfilment is another crucial touchpoint many retailers will have with their customers. At the end of the day, the relationship is based on them receiving the product from you. In a time when in-person and in-store transactions are limited if not completely gone, this will be one of the main physical connection you will have.

Have a strong shipping partner to maintain this crucial connection with your customers.

Conclusion

The bottom line will always be number one, but the idea of being able to help each other for mutual benefit will become a more commonplace value moving forward. The basic livelihoods of people will depend on it.

Businesses who are able to quickly forge new connections and make new partnerships will be the ones who remain nimble and are able to face challenges and uncertainty in the short term and in the future.