Amazon order management process: harness chaos for efficiency

Amazon is the undisputed world leader when it comes to online retail. They have remained one of the most dominant online marketplaces for the better part of a decade and have even developed their own Amazon order management process. In 2015, Amazon’s annual sales topped $107 billion. By the end of 2019, net sales had grown to $280.5 billion.

One of the biggest reasons for Prime’s success is the instant gratification customers get when ordering a product. You may be surprised to know that Amazon’s secret to moving inventory at breakneck speeds lies in the deliberate chaos of their warehouses.

Yes, chaos.

Unlike the majority of marketplaces, an Amazon warehouse stores virtually all its products in-house. To stock this extraordinary amount of inventory, Amazon requires quite a bit of real estate. Weighing in at approximately 150 million square feet of storage space spanning across a multitude of warehouses, Amazon has one of the world’s largest storage spaces. There are more than 100 in the United States alone, each with at least a 100,000 square foot floor plan.

As you can imagine, trying to control that much inventory can be a logistical nightmare. To manage effectively, Amazon took a different approach to create efficiencies. It’s using purposeful disorder to its advantage.

In this article, we will explore how Amazon created their own order management process and how you can implement this technique in your warehouse to increase receiving, picking, and shipping times.

What is the Amazon order management process?

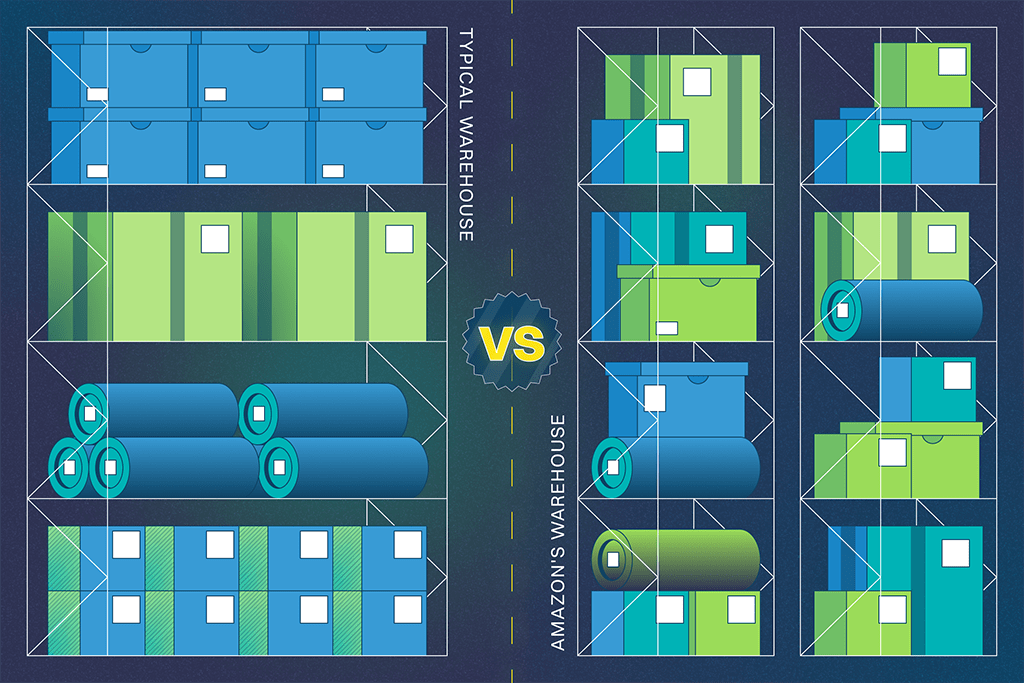

When people think of an organized warehouse, they imagine rows of neatly managed shelves stocked with similar products arranged methodically by alphabet, SKUs, or some other metric. However, because of automated inventory and warehouse management systems that utilize barcodes and barcode scanners, warehouses like Amazon are able to enact a system known as “chaotic storage” to manage their storage facilities.

The Amazon order management process (chaotic storage) is a system wherein incoming products are placed randomly on available shelving space within a given warehouse with disregard for itemized locations.

While this method may sound counter-intuitive, in actuality it can increase warehouse efficiency and streamlines processes.

A company that relies on manual processes, such as Excel spreadsheets or a home-grown inventory management system, wouldn’t dream of implementing this method and for good reason. Chaotic storage requires a robust and comprehensive inventory management system (IMS). Without one, warehouse managers would have no clue where items were located. The chaos would be literal chaos on the warehouse floor. It might resemble a scavenger hunt during order fulfillment time.

Why is chaotic storage important?

Each month, nearly 200 million people shop at Amazon.com. That’s more than the entire population of Russia. When shopping, they may be looking at any number of the eCommerce giant’s 129 million available products – not including those on Amazon Marketplace!

Amazon serves more than 300 million customers and has built its reputation around its innovative delivery capabilities. In its quest for even faster delivery, it added Amazon Prime Now, which allows customers in select cities to order common household items and groceries from Whole Foods online and have their products delivered in 2 hours or less.

Consumer demand for Prime Now and Amazon Prime indicates that there is a growing trend emerging which requires companies to have faster shipping processes. The coronavirus pandemic (COVID-19) increased consumer demand for shopping at home and home delivery. This revolutionary approach to inventory management and delivery created a need that requires an equally revolutionary solution.

After assessing Amazon’s warehouse structure, it becomes obvious that the traditional warehouse approach would not work for them.

Spreadsheets are prone to produce inaccurate records due to basic human error and cause slower lead/fulfillment times, out-of-stocks, mis-ships, and inefficient use of storage space. However, thanks to the capabilities of inventory management software, Amazon’s warehouse managers and staff know exactly where every item is shelved – despite their random placement throughout the warehouse. They are able to advise pickers about which routes to take to fulfill multiple orders in the shortest amount of time.

Inventory management is the secret sauce behind Amazon’s astonishing fast order fulfillment, delivery capabilities, and accuracy and is something that every company needs to stay competitive.

What are the benefits of chaotic storage?

Coupling chaotic storage and an inventory management software enable you to take control of your warehouse and provide a wide range of benefits, including:

Increased flexibility

Empty storage space is filled up immediately. This means less waste of valuable storage space.

Better space utilization

Implementing chaotic storage forces owners to organize their locations more efficiently which enables you to store more products better. The company says that using chaotic storage allows them to store twice as many goods as they did five years prior to implementation.

Fewer picking errors

While it may seem odd to stock your products at random, the company claims it helps employees avoid mix-ups and mis-ships, such as grabbing the wrong size or color item. When T-shirts are grouped together, it can be easy to grab the wrong size or color. When they’re in the same bin and books or lamps, it acts as an added layer of protection against picking errors.

Simplicity

For new employees, it can be difficult to learn where everything is within a warehouse. Inventory management takes the guesswork out of the picking process and tells employees exactly where to go and what to pick. This makes it easier to onboard new team members and deal with turnover.

Warehouse optimization

Warehouses can be overwhelmingly large. Chaotic storage eliminates the wasteful back and forth movements to fulfill an order with varied contents. These management systems can compute an optimized fulfillment route.

Faster racking and slotting

With chaotic storage, locations are determined by the warehouse management software according to parameters, such as available space, weight load, and route optimization. Workers don’t need to spend time organizing locations or hauling goods to remote areas of the warehouse when there’s opening closer.

How does chaotic storage work?

There are a few key points about what makes chaotic storage work. It takes a slight change in thinking when it comes to identifying products and locations, as well as the picking process.

Identifying products and locations

Chaotic storage is only possible with inventory or warehouse management software. This software is able to aggregate information about specific products and their locations by employing the use of barcodes and barcode scanners. These systems allow users to print barcodes that can be used to organize and track inventory across multiple warehouses. Barcodes hold data that can be read by a barcode scanner and used to differentiate and track individual items within multiple warehouses.

Each pallet, SKU, shelf, and bin can have a barcode that can be scanned and read to track the exact location and quantity of every item in a warehouse or across all warehouses a company operates.

Users are also able to use pre-existing product codes and SKUs (Stock Keeping Units) or create their own using their inventory management software. These barcodes are scanned into various locations throughout the warehouse. After SKUs or barcodes are scanned, the warehouse’s inventory management system then keeps detailed records of which items are where, how many items are located in a specific location, and anytime an item is added or removed from a location.

Picking

At a company like Amazon, orders come in abundance so it is not enough for pickers to just know product locations. To keep up with orders, pickers need optimized routes and processes. Data collected on products and locations are used to map out the most optimal routes for pickers.

Instead of picking orders one at a time, pickers are able to pick orders in batches. So, instead of running all over the warehouse to fulfill orders, management software will tell employees how many orders need to be picked, where it is, and the best route to get to it. Since travel time in a warehouse picking operation accounts for as much as 50% of work hours, optimized routes can create significant savings on labor costs, not to mention the wear and tear on the pickers.

This eliminates wasted time on overlap created by going to the same location multiple times to complete separate orders. These features alone are a tremendous help, but they’re really just a fraction of inventory and warehouse management systems capabilities.

Implementing chaotic storage

You may be thinking this all makes sense for a company the size of Amazon but will it work for me?

First, you need to take a hard look at your current warehouse structure and make some assessments. If you currently do not have an inventory or warehouse management software, such as SkuVault, don’t even think about using chaotic storage.

If you don’t have an IMS already, you’re likely not maximizing your resources right now for any processes or procedures you implement. The average U.S. retailer has an accuracy rate of just 63% on its inventory.

Fix this problem before looking at additional solutions. Just implementing an IMS, such as SkuVault Core, can solve this frustrating problem. eCommerce retailers using SkuVault Core report 87% faster fulfillment, 90% fewer out of stocks, and 83% fewer mis-ship.

After you decide what management software works well with your business you are ready to get to the real work. Implementing an inventory management system can take some time, so you will want to make sure you are prepared.

You will need a master list of all your products that includes information like:

- Item numbers

- Units of measure

- Descriptions

- Purchase cost

- Vendor information

- Other pertinent information

Gathering this information ensures that you will have all the information you need to import into a management system.

Now it’s time to put those barcode printers to work. Start rebuilding the structure of your warehouse by establishing locations with unique barcode identifiers. These locations will serve as storage space for your products which will also be barcoded. Then create SKUs to identify products you place in these locations. After you have implemented your management software, and have scanned your newly barcoded products into now established locations, you are good to go.

Common questions about the Amazon order management process & inventory management

Here are some of the common questions you may be asking about warehouse operations and how to implement chaotic storage in your facility.

Without being able to visually scan inventory, how do I make sure all of my marketplaces and platforms are showing the right inventory?

In a chaotic storage process, you won’t be able to glance at a shelf and instantly see you’ve got a dozen items lined up. They may indeed be spread out across your facility. With the right inventory management software, that won’t matter. SkuVault keeps all your inventory constantly up-to-date across every connected platform and marketplace. From one central database, you can automatically update inventory counts to make sure you never run into oversell situations.

Quantity buffers can ensure you never sell out of products regardless of the number of places you list your products for sale.

What about re-ordering?

Some warehouses still use whiteboards, tally sheets, or Excel spreadsheets to track inventory levels. For even the smallest eCommerce retailers, this is barely manageable. As your inventory grows, so does the complexity. SkuVault Core tracks your entire supply chain, forecast and track reorder points, analyze selling patterns, and automate the process. The replenishment report is a particularly valuable tool when it comes to making smarter and faster purchasing and reordering decisions.

Can all items be managed with a chaotic storage solution?

No. There are some exceptions, such as items that need special handling or when climate control is necessary. For example, refrigerated items can’t be stored on open shelves, but chaotic storage could be implemented within refrigerated areas.

What’s the difference between an inventory management system and a warehouse management system?

One common trait among entrepreneurs is that they are always on the lookout for more functionality from their systems. You may have noticed that I use inventory management and warehouse management interchangeably in this article, but in actuality, these systems are not the same.

At a base level, all you need to achieve chaotic storage is an inventory management system, but my guess is that you would prefer something that is able to go beyond the basic functions. If this is true, then you may be more interested in a complete inventory management system and warehouse management system that is able to create complete control over the entire process from start-to-finish.

The biggest difference between these management systems is that a warehouse management system provides more functionality. Warehouse management systems have the power to unify your entire business through powerful integrations. These integrations automate different areas of your business such as accounting, shipping, inventory management, and more. By automating different areas of your business, you gain a more streamlined, organized, and an error-free business structure that will boost your overall performance.

Conclusion

If physical retail stores were laid out the way Amazon’s warehouses are, you would have real chaos. Bread on shelves with TV sets. Aspirin mixed in with auto parts. Shoes next to pillows. It would be impossible for shoppers to find anything even with a store map!

In the Amazon order management process using chaotic storage in a warehouse, however, locations are largely irrelevant. Items are stored anywhere and workers rely on software to track its location and optimize retrieval. It speeds up the storing process and can cut down on space requirements since available storage space is used more efficiently.

Regardless of whether you stick to traditional storage methods or decide to test out chaotic storage, you need a robust inventory management system and warehouse management system that can do the job. Contact us today for a demo.

From supply chain to shipping, SkuVault Core and Linnworks helps you sell faster, pick faster, and ship faster.