Master the Basics of Barcode Inventory Management [And How to Implement Your System]

In the commerce world, many merchants utilize barcode inventory management to streamline their operations.

A barcode inventory system can minimize error, save on payroll, and improve your ordering. Aside from affordability and increased efficiency, there are many benefits to adopting a barcode inventory management system.

And yet, some businesses still don’t understand what it means or how to use it properly.

Throughout this article we will uncover how barcode inventory is able to transform the disarray and chaos of a warehouse, and turn it into a well-oiled machine fit to tackle any inventory discrepancies you may be facing. You will learn:

- What are barcodes and how do they work?

- How to implement an inventory barcode system

- The benefits of barcode inventory management software

- How you can get started with barcode inventory management

Warehouses have evolved from being a neglected cost center into a strategic hub for eCommerce and ever-growing supply chains. Efficient warehouse operations, using an inventory barcode system and inventory management software are key to unlocking profits.

What Are Barcodes?

A barcode is a machine-readable code in the form of numbers and patterns of parallel lines of varying widths printed onto a product for identification.

In 1948, Bernard Silver and N. Joseph Woodland created the first barcode. It was a bullseye pattern that was read by a crude type of photoelectric cell to read reflected light. The process evolved over time and in 1971, an IBM engineer developed the Universal Product Code (UPC), which became the industry standard and is still in use today. It was first implemented at a grocery store in Troy, Ohio where the first scanned purchase – a 10 pack of chewing gum – was purchased.

These UPC codes became the standard for external product tracking. The same basic technology is used in today’s SKU codes that are used internally by companies to track products. While UPC codes are consistent in every environment, each company assigns its own SKU numbers. These numbers are distinctive from UPC codes and product model numbers that may be assigned from manufacturers.

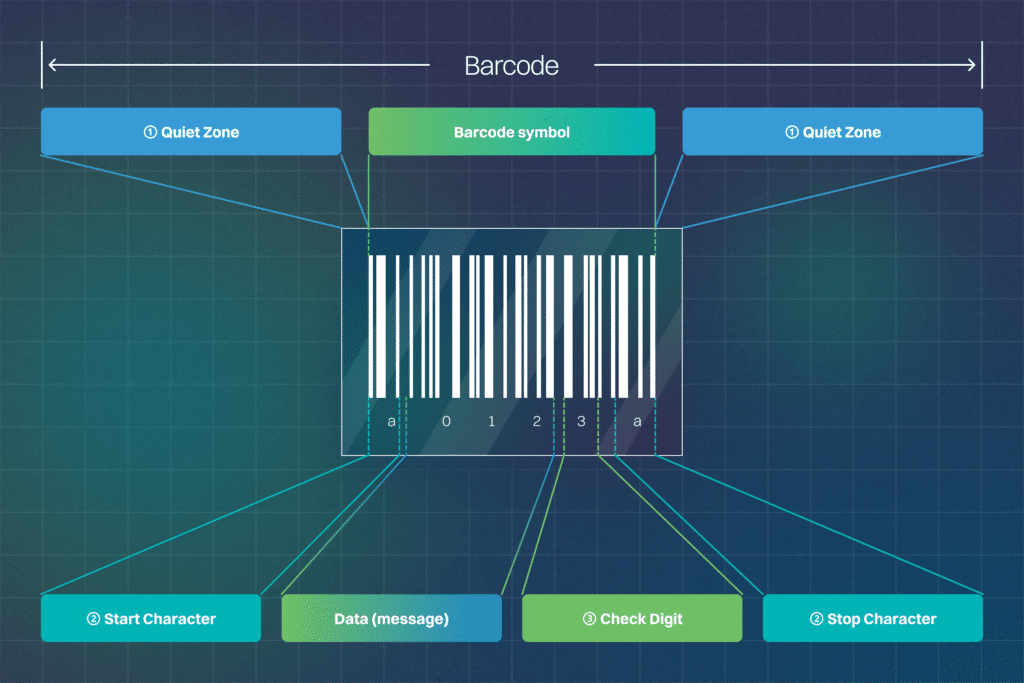

Although each type of barcode is a machine-readable code in the form of numbers and patterns of parallel lines of varying widths printed onto a product for identification, barcodes on SKUs typically consist of five parts:

The Five Types of a Barcode

- A quiet zone

- A start character

- Data characters (including an optional check character)

- A stop character

- Another quiet zone

All of these symbols are what makes each barcode, and subsequently each product, unique in an inventory environment.

A barcode reader is required in order to read the code. The reader uses a laser beam that is able to sense the reflections from the lines as well as the space thickness and reformat that pattern into a number in a digital format.

Inventory systems, POS systems, etc. use this digital format to transfer information about that product to various locations where users can make smart decisions about their product and business based on the data that is collected.

Why are Barcodes Important?

One thing to keep in mind about barcodes is that there are many different types, and they serve vastly different purposes. These purposes differ for various reasons.

Some are different simply because of the country and its usage, while others differ because of functionality. Generally speaking, there are approximately 15 different types of barcodes.

However, barcodes are entirely customizable and can be adopted for unique use cases depending on what inventory barcode system you use, and your specific tracking needs.

For example, at SkuVault, we recommend that our clients create barcodes for their locations within their warehouse and product SKUs in conjunction with UPC codes. The SKU barcodes are customizable to your operation.

Both are great for optimal tracking. By using barcode inventory, pickers and other users are able to find, track, and ship items with ease.

SkuVault uses Code 128 encoding, making our barcodes readable by most scanners including the CT10.

The Code 128 barcode doesn’t mean it includes 128 characters. Rather, its name reflects the fact that it can include any character in the ASCII 128-character set, including numbers, letters, and punctuation marks. This gives you more characters to use to store diversified information while maintaining a compact size for data storage.

Code 128 is the most common format used for logistics for ordering, distribution, and transportation. While UPC codes are used more commonly at point of sale, code 128 barcodes are used in warehousing operations.

[html_blocks id=”20106″]

How to Implement a Barcode Inventory Management System

Many companies that do not use barcodes for their inventory are slow to adopt new systems because they fall victim to a sort of logistics paralysis. When they think of implementing a new system, doubt begins to arise. They fear the amount of work it will take and would rather continue with an inaccurate count and inefficient systems they currently have in place.

Implementing a new system can be tedious and takes time. Managers find it simpler to put off implementation until some arbitrary date, or in many cases, they either don’t know where to start or don’t want to go through the process of installation.

Those that do make the switch see results almost immediately. Statistics show that warehouse personnel levels can be decreased by about 20%, saving on payroll and associated labor costs. With high turnover levels and the increased difficulty in recruiting warehouse workers, having fewer jobs to fill is a nice benefit.

Inventory levels also tend to drop after a barcode inventory system is put in place. With more accurate counts, there’s less concern about running out of stock on items. This means less safety stock to keep on hand with an efficient inventory management system that connects with suppliers and helps manage lead times.

Barcode inventory management software and an inventory barcode system work together to create a strong ROI. “Barcode systems generally pay for themselves within 6-18 months,” according to Barcoding Incorporated. Once this return on investment is realized, the savings from that point forward can go right to the bottom line.

Start With a List

As the old saying goes, “There is no time like the present.” Regardless of where you are with inventory, swiftly and aggressively implementing a solution is best.

Managers should start by making a master list of everything that might be in their warehouse or stockroom. This list should include item numbers, units of measure, and descriptions at a minimum. You may also include:

- Purchase cost

- Vendor information

- Minimum inventory amount

- Safety stock and reorder levels

- Other pertinent information associated with all items

Aggregating this information ensures that you will have all the essentials for importing product information into the inventory management system you choose.

SkuVault Inventory Management System makes this process simple with an easy-to-use import feature. If you don’t have a master list of products with this information, simply ask your suppliers for the information. This will decrease the amount of time spent pulling the initial information together.

Putting Barcodes on Inventory

Many items purchased already come with barcodes attached. If the barcodes already exist, congratulations! You have already saved a great deal of time.

While you can create unique custom barcodes for any product, you can also use those already in place and add custom barcodes to products that aren’t pre-printed with them.

To create your own inventory barcodes, you’ll need a barcode printer. You can get started with a barcode font (an IDAutomation software). Barcode font gives you an inexpensive and flexible way to print high resolution labels quickly.

Even if your products do come with barcodes, you may want to purchase a barcode printer so you can establish product locations within your warehouse or stockroom. These can be scanned and tracked, too. Many operations also find it useful to relabel items with their own barcodes. You do need to make sure the barcodes match the item numbers on your master list.

Putting Barcodes on Shelves and Bins

In addition to products, you will want to consider putting barcodes on shelves and bins within your warehouse. This makes it easier for your pickers to navigate the warehouse and gives you an additional way to make sure inventory is placed in the right bin or shelf when it is received.

The Benefits of Barcode Inventory Management

Smart inventory management is a key component to the overall growth of any company. Those who manage inventory are responsible for keeping up with inventory levels, out of stocks, product locations, tracking, receiving, shipping, and more.

These responsibilities are crucial. Mistakes made in these areas can be costly. Mismanagement of inventory can lead to lower sales, decreased market share, increased inventory cost, and frustrate customers who may go to your competitors to buy. It can decrease your reputation and customer loyalty.

Companies that don’t utilize a robust inventory management system and barcode inventory management system are notorious for inaccurate stock levels. One comprehensive study of retail operations in the United States reported an inventory accuracy of just 63%. That means at any one time, retailers are unaware of the status of nearly a third of their inventory.

Human error is inevitable. No system is going to totally eliminate it. However, adopting barcode inventory management, errors will decrease dramatically.

Why Companies Use Barcoding

An inventory barcode system is a more reliable and efficient method of inventory management. To alleviate manual processes, barcode inventory management allows managers to perform their duties in a more convenient and efficient manner. Thus, resulting in increased accuracy and faster processing. Companies use barcoding because:

- It is simple to use

- It is cost-effective

- The technology is easily available

- Barcodes eliminate errors

- Barcodes provide security

- Inventory tracking with barcodes saves time

Without an inventory barcode system, the workload and number of tasks become an unnecessary burden on inventory managers. Managers have to manually write down important figures and information about products or manually enter it into spreadsheets. Critical information can get lost, typos can occur, and products can be destined to become dead stock.

Every stroke of the pen and button pressed on the keyboard opens up room for human error, and if not caught immediately, chances are the mistake will go unnoticed until it results in a problem. Using outdated methods and software like Excel, along with pen and pad methods, are simply unreliable.

Benefits

No matter the business you’re in, you most likely have inventory that has to be managed. Whether you have items for sale, raw materials, finished products, tools, parts supplies, etc., barcode inventory management comes with lucrative benefits, such as:

- Know exactly how much of each SKU you have on hand

- Know exactly where it is in the warehouse (and which warehouse)

- The ability to receive, stock, move, pick, and fulfill orders from any inventory item

- Relevant and real-time reports about available inventory, pending inventory, orders, and reorder times for all SKUs and raw materials

- Simple process to enter and extract data for better business intelligence

- Easier and more efficient cycle counts

- Export data easily to your accounting or other back-end systems

Flexible Pick and Sort Strategies

Barcode inventory management software makes it easier to adopt flexible pick and sort strategies in your warehouse.

Batch picking and sorting are becoming increasingly common due to its cost efficiency when processing large amounts of small orders quickly. Multiple orders can be picked at the same time to reduce travel times during the pick process. They can be grouped into bins or sorted at shipping.

For busy warehouses, it can reduce the number of staff required on the floor, cut down on traffic congestion, and allow orders to be grouped in zones to optimize operations.

Why a Barcode Inventory System is More Important Now Than Ever

As eCommerce sales have grown, so have the number of SKUs that companies are offering. With retailers selling on multiple platforms and marketplaces, the product mix has grown as well. More SKUs being sold in more places means more possibilities for errors.

Speed and Agility

For consumers, time to fulfillment has become a key competitive advantage. Companies that can more quickly pick, pack, and ship orders stand to do better in today’s environment.

Amazon has set the tone for the industry with free and fast shipping, including its Amazon Prime program. As customers have become used to getting goods quickly, it has put more pressure on companies to manage their inventory tightly.

Being unable to fulfill orders on Amazon or other marketplace providers efficiently can have a huge impact on your sales and hurt your seller ratings. On average, nearly 70% of customers say they will not do business with a company again if their delivery is later than promised.

That doesn’t take into account things such as stock-outs and backorders. Speed and agility are critical elements of customer satisfaction.

Reverse Logistics

There’s also a growing concern for eCommerce sellers about reverse logistics. In January 2019, UPS processed more than 1.9 million returns.

That’s an increase of 26% from the previous year and that’s just at one shipping company. Online shoppers tend to return goods more often.

A study by Deloitte revealed a 30% product return rate for eCommerce sellers. The cost to the U.S. and North America businesses in returned goods exceeds $246.3 billion annually.Without a robust tracking system and process to handle reverse logistics, losses to eCommerce sellers can be substantial.

Summary

The problems that arise from not using a barcode asset tracking system far outweigh any costs associated with implementing an efficient inventory barcode system.

When everything is accurately tracked and placed with a warehouse, the job of your stock pickers is significantly easier. Done properly, there are no more lost items.

Pick lists can be fulfilled faster with optimized routing. You will always have an accurate count of inventory and know the value of what’s in your warehouse.

The right IMS will sync your inventory across multiple platforms and marketplaces to avoid out-of-stock situations. From one dashboard, you will be assured your stock will be managed and maintained with no lost orders. After you have labeled products, designated locations, and imported product info into your new inventory management software, you have successfully taken your first steps in implementing a new barcode inventory system.

These steps are going to take some time, but the good news is that the hardest part is behind you. Now you can rest easy knowing that you have eliminated most of the inaccuracies in your warehouse and can expect to see ROI as a result in saving from mis-picks, mis-ships, out of stocks, and human error.