Inventory visibility: strategies, benefits, FAQs

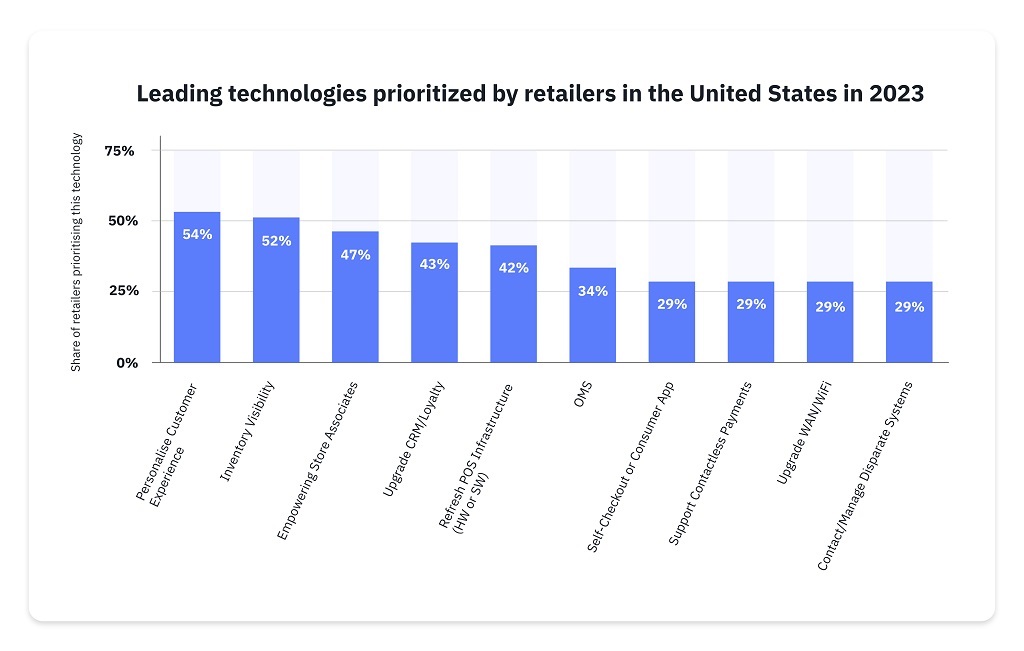

Inventory visibility is one of the leading technologies prioritized by retailers. Yet, for many business owners and managers, inventory feels like a mystical creature lurking in the shadows.

But it doesn’t have to be that way. Effective inventory management doesn’t need to be a left to chance. Not when you utilize the right inventory visibility tools.

In this article, we dive into all things inventory, explore the innate challenges of inventory visibility, and look at some winning strategies and dedicated inventory visibility software tools your business can utilize to optimize supply chain management for a seamless customer experience. Let’s get going!

What is inventory visibility?

Inventory visibility refers to having a clear real-time view of available stock and quantities across all locations, warehouses, and selling channels. Accurate inventory visibility ensures smooth operations, satisfied customers, and a thriving online business.

Why is inventory visibility key to efficient supply chain management?

Inventory visibility is essential for efficient supply chain management as it provides real-time stock insights across locations. This helps businesses meet demand, reduce stockouts, optimize storage, and streamline fulfillment, leading to higher customer satisfaction and profitability.

Think of inventory visibility as the ultimate trust-building potion, allowing you to:

- Accurately showcase your products

- Avoid overselling stock.

- Provide real-time information to stakeholders across your entire supply chain.

For the longer version, picture this scenario: A customer visits your website, falls in love with one of your products, and excitedly clicks the “Buy Now” button. But then the bubble bursts. Turns out the product is out of stock, and now you’re left with a disappointed customer as well as a lost sales opportunity.

That’s why managing inventory levels is essential. Full inventory visibility is a magical elixir that allows you to see through the fog. It’s like having X-ray vision, giving you a clear picture of exactly how much inventory you have and where it’s located.

What are the benefits of improved inventory visibility?

Improved inventory visibility has myriad benefits, ranging from improved order fulfillment to a seamless customer experience. By taking control of your inventory visibility, and ultilizing an inventory visibility software, you can unlock these benefits and take your ecommerce operate to new heights.

Let’s look at the variety of ways increasing inventory visibility can help your store optimize operations:

Improved order fulfillment processes

If you want to meet customer expectations every time, mastering the art of timely delivery is a must.

People who buy your products are excited to receive them. They’ll eagerly track their order as it’s processed, leaves the fulfillment center, and makes its way to their address. So, knowing exactly what’s in stock, where it is, and how quickly you can get it into their loving arms is key to ensuring customer satisfaction.

Reduced stockouts and overstocks

Ah, the age-old inventory data conundrum: too much or too little? Fear not, Goldilocks! With the right systems in place, your stock levels will be “just right” every time.

With the ideal amount of safety stock to ensure no barren shelves or overflowing warehouses, you can kiss goodbye to stockouts that crush the customer experience, wave farewell to overstocks that gather dust and drain your profits, and say hello to complete inventory control.

A seamless customer experience

The goal isn’t just to meet customer demand. It’s to exceed customer satisfaction expectations and guarantee the kind of service that leads to glowing reviews and a reputation that shines brighter than a disco ball.

With accurate, up-to-date inventory analytics at your fingertips, you can give real-time answers to customer inquiries, eliminating potential frustration and providing a silky-smooth customer experience.

More effective inventory control and planning

Imagine having a crystal ball that can teach you how to manage and monitor stock levels, reduce shipping costs, and still nail the fulfillment process every time. Well, improving inventory visibility does precisely that!

With real time inventory insights, you’ll have accurate data providing a clear view of your stock levels, demand patterns, and market trends, empowering your team to anticipate demand, forecast growth, and maintain healthy inventory levels across all seasons.

Minimum carrying costs and maximum profit

Gaining a clear and accurate understanding of when to restock reduces warehousing fees and the carrying costs associated with excess inventory and unnecessary storage.

In other words, better inventory visibility gives you a sixth sense for maximizing sales. Plus, you can ensure optimum profitability by minimizing supply chain expenses like shipping costs and third party logistics. Cha-ching! It’s the winning combination with the power to completely revolutionize supply chain management.

What are the challenges of inventory visibility in supply chains?

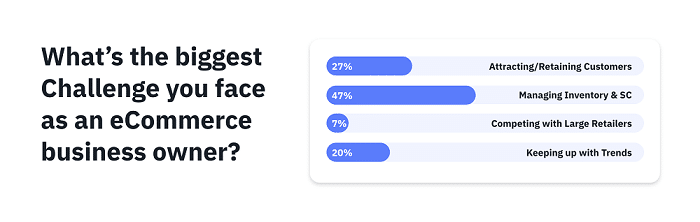

In our LinkedIn survey, 47% of ecommerce owners voted supply chain and inventory management as their biggest business challenge – significantly outpacing issues related to customer satisfaction, competing with larger retailers, and keeping up with industry trends.

But why? In today’s fast-paced, digital world, surely it shouldn’t be rocket science for businesses to get a handle on how much inventory they have?

We dug a little deeper and found several common barriers to increasing inventory visibility.

Data silos

Data silos are like sneaky invisible dividers that separate your inventory information into isolated pockets.

Different departments and systems in your supply chain hold crucial inventory data, but when there’s insufficient integration and communication between selling channels, fulfillment centers, and distribution centers, it’s nearly impossible to achieve full visibility and gain a holistic view. This fragmented knowledge leads to discrepancies, delays, and missed opportunities – and essentially makes determining how many units of stock you hold a matter of guesswork.

“We were selling on both eBay and Amazon, but we started having issues with managing stock across the channels. We didn’t have any processes in place and everything was disorganized.” – Anthony Rowe, Managing Director at Goldstar Leisure

Outdated systems

Imagine trying to win a race against a sleek, high-performance motorcycle when you’re riding a vintage bicycle.

That’s what it’s like trying to compete against businesses using a proper inventory management system when you remain reliant on systems that lack the agility, flexibility, and connectivity to provide real-time visibility. Outdated technology slows you down, compromising your ability to make informed decisions, provide a positive customer experience, and maintain a competitive edge.

“Our previous system didn’t provide an open API – which meant that we couldn’t link up our clients and various other software to the system, causing frustration all around.” – Rich Moore, Co-founder at BMX Source

Manual processes

Ah. yes. The good old paper trail nightmare. A tale as old as time.

Relying on manual data entry, spreadsheets, and paper-based records introduces a slew of challenges. Not least the potential for human errors, delays in information updates, and the inability to handle large volumes of data. The long and short of it: manual inventory tracking is a relic that belongs in the past.

“We were working from pieces of paper in the warehouse and grew to a size where it wasn’t sustainable anymore. We came to a point where we started to lose more stock and found it very difficult to know where stock was located.” – Simon Ball, Operations Director at Tootonic

Inadequate integrations

You can’t pull off a symphony when every instrument in the orchestra is following its own rhythm.

When systems and platforms fail to communicate seamlessly, it hampers the flow of information and inhibits real time inventory visibility. For instance, if your inventory management system doesn’t integrate with your sales platform or warehouse processes, you end up with information gaps, duplicated efforts, and difficulties tracking stock movements.

“We’d run into problems of overselling if we sold out products on one place and didn’t manually update the quantity somewhere else quickly enough. It was a lot of work that never ended.” – Aaron Peterson, owner of Macdaddy Music

What are the best ways to improve inventory visibility?

The best ways to improve inventory visibility include using inventory management software, integrating systems across channels, and adopting RFID technology. These tools offer real-time tracking, reduce errors, and ensure accurate stock data across all locations.

Let’s consider these individually:

Implementing inventory management software

Robust inventory management software acts as a beacon, illuminating the path to more accurate inventory counts and better overall inventory management. It gives you real-time insights into stock volume and movements through automated data collection and tracking, helping you streamline supply chain operations and inventory levels across all locations.

Through inventory visibility, we’ve been able to provide up-to-the-second updates on what we have available so that customers aren’t caught off guard with out-of-stock notifications.” -Nabeel Abdullah, Founder and CEO, Sapphire

Dedicated enterprise resource planning software from Linnworks helps you say goodbye to manual processes and hello to smart order management, empowering you to:

- Avoid stockouts and excess inventory across multiple locations with automated inventory management tools

- Forecast demand accurately with real-time data on historical sales and current consumption levels

- Synchronize inventory levels everywhere you sell through 70+ marketplaces and multichannel integrations.

- Streamline workflows and make data-driven decisions from one central dashboard

- Nurture more efficient supplier relationships with automated end-to-end purchase order processing

- And so much more!

Integrating systems across channels

When systems across different sales channels play nicely together, magical things happen. By integrating order management, sales platform systems, and inventory management software, businesses can achieve unified inventory accuracy.

Seamless integration functionality eliminates data silos, synchronizes information, and enables businesses to track inventory across all channels in the supply chain. When every sales platform operates using the same set of inventory data, the risk of overselling or underselling is eliminated.

“The implementation of an automated system has enabled us to streamline our operations by providing real-time data on stock availability and replenishment needs across all locations.” – Vaibhav Kakkar, CEO, Digital Web Solutions

Linnworks integration allows you to connect marketplaces, ecommerce platforms, and major carriers with any 3PL fulfillment center or FBA. alternatively, you can use our open API to allocate inventory and integrate your unique ecommerce ecosystem.

Advanced RFID technology

Radio Frequency Identification (RFID) asset tagging tools have the power to revolutionize inventory tracking and visibility.

RFID tags and readers allow businesses to remotely monitor and track inventory with exceptional accuracy – a superpower that boosts efficiency and minimizes errors. Specific RFID inventory visibility benefits include:

- Effortless traceability – Track stock across all inventory locations, regardless of whether products are stationary or on the move.

- Hundreds of hours saved – No more laborious manual entry processes to get an accurate inventory count.

- Improved data accuracy – Fewer manual data entry errors.

- Updated asset lists – Remove ‘ghost’ assets that have been lost/stolen within the historical supply chain lifecycle.

- Theft reduction – Excess inventory and safety stock cannot be moved around unmonitored.

- Meet customer demand – Give more accurate estimations of shipping costs and arrival times.

Case Study: Successful implementation of inventory visibility

Looking for more real-world knowledge and inspiration on supply chain visibility and inventory management? You got it! Let’s take a look at one of Linnworks many success stories — Graff City.

Graff City is a graffiti and spray paint supplies business based in Wales, UK. Since its inauguration in 2012, the company has grown from a one-man bedroom start-up to a multi-million-pound enterprise offering an extensive range of art tools and clothing for amateur and professional artists.

The Problem: Outdated spreadsheets and manual inventory tracking led to overstocking and underselling.

Before reaching out to Linnworks, the Graff City team relied on manual processes to manage inventory levels. But using multiple static spreadsheets to track stock and create sales forecasts was a time-consuming and error-prone endeavor. Plus, the lackluster warehouse management system made making accurate manual inventory counts a Herculean task.

Month after month, the team found themselves overstocking and underselling, even as customer demand increased and product lines grew. It was time to take the inventory visibility matter in hand once and for all.

“We were either holding on to too much stock, the wrong stock or not having the right products available because we didn’t have the stock – meaning customers could have gone elsewhere.” – Graff City.

What Graff City needed was a warehouse management system and integrated inventory management software that could grow with its business needs as the company scaled.

The Solution: Linnworks stock forecasting

Linnworks stock forecasting allowed Graff City to replace their manual processes and spreadsheet chaos with accurate inventory numbers from which the team could make data-driven decisions. The Linnworks stock forecasting model predicts demand-based inventory levels by analyzing historical data from past orders and factoring in additional considerations like seasonal fluctuations.

With more inventory visibility regarding current stock levels, future orders, and general best practices for sales maximization, Graff City was able to forecast sales, lead time, and desired stock levels to see exactly when they needed to order extra inventory across a vast range of products.

The Results: Increased efficiency and enhanced profitability

It wasn’t long before the team began to witness the significant benefits of inventory visibility. Accurate demand forecasting allowed the team to plan ahead and identify consumer demand patterns and trends on a monthly basis while simultaneously saving hours of laborious admin, data entry, and manual manipulation.

“Because of stock forecasting, we’re no longer holding on to too much or the wrong stock, or not selling enough of the right stuff because it’s out of stock. What used to be a lengthy process taking the majority of 1 day per week can now be done within 30 minutes. This not only saves a lot of time but also provides more accurate re-ordering figures.” – Graff City.

Graff City currently offers an ever-growing product variety and is successfully scaling globally in partnership with Linnworks.

Download the full case study PDF, and find more inspirational client success stories by checking out more Linnworks case studies.

Start your journey towards full inventory visibility today

Inventory visibility continues to play a critical role in ecommerce success. Inventory visibility software is the skeleton key you need to unlock operational efficiency, make more accurate data-driven decisions, and reduce supply chain costs. It’s a win, win, win for your online business.

Ready to increase inventory visibility across your organization? Book a free demo today and get set up on the path to scalable growth and success.